Real-Time Inventory & Smart Restock

Ensure smooth operations with our garage inventory management software.

Streamline Your Inventory Management for Maximum Efficiency

Our intuitive system allows you to track stock control, reorder management, and usage patterns. Analysis of these will help ensure that you’ll never run out of anything without over-ordering. Comprehensive oversight improves your efficiency. What’s more? Supplier performance insight, an invaluable source that can help make educated decisions concerning vendor relationships and procurement strategies.

- Track parts and stock levels.

- Automatically reorders to prevent shortages and overstocking.

- Monitors supplier performance to make better judgments.

- Cash inflow is enhanced by the effective management of your stocks.

- Better Service Delivery: getting needed parts promptly.

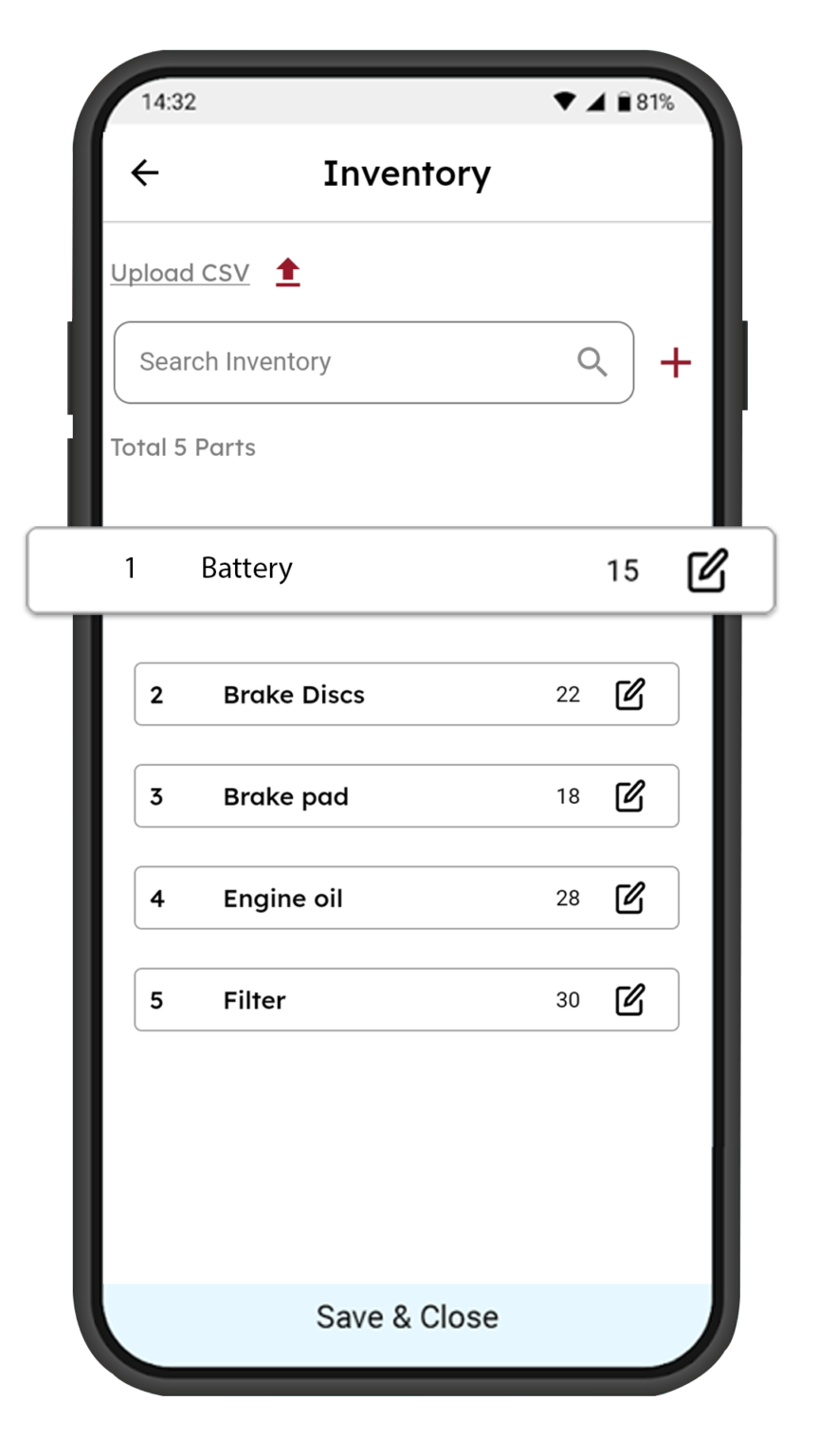

Streamline Your Operations with VR Garage Inventory Management

Say goodbye to stock shortages and overstock issues with our Garage Management Software. Tailored for auto shops, this powerful tool allows you to monitor stock levels, track product movement, and manage suppliers with ease. With real-time inventory updates, automated reorder alerts, and detailed reporting, you can ensure that you always have the right parts on hand when you need them. Enhance your operational efficiency, reduce waste, and improve customer satisfaction by managing your inventory smarter. Experience the difference with VR Garage Inventory Management and keep your shop running at peak performance!

- World-Class Operations

- Efficient & Organized Management

- Intelligent Data At Your Fingertips

- Quick Branding

- Integrated Marketing Solutions

Better Garage Management

5x Revenue

VR Garage is your all-in-one garage management software, allowing you to manage operations, simplify workflow, and collect payments all in one platform. Take control of your garage operations with the best in business!

Schedule a free demo

Get in touch with our team to clarify your queries

Still unsure? Find the answers you’re looking for.

It’s the process of tracking stock levels and orders to prevent shortages and overstocking.

It provides instant updates on stock levels, enabling quick responses to changes in demand.

It predicts future product demand using historical data, helping adjust inventory levels accordingly.

It automatically reorders stock when levels fall below a set threshold, ensuring timely restocking.

They offer insights into sales trends and stock performance, helping businesses make data-driven decisions.

No hidden fees! You can choose a subscription plan that suits your business size and start using VR Garage immediately. One-time setup or onboarding support may be optional depending on the plan.

Absolutely. In both cases, the goal remains the same: to enhance garage’s operations, improve customer satisfaction, and drive growth. Whether you’re a small independent mechanic shop or a larger multi brand workshop, VR Garage provides tailored solutions to meet specific business needs and help you excel in automotive industry.

Absolutely, VR Garage software can give your garage a powerful competitive edge. By modernizing your customer experience and garage operations your business can set apart. This digital approach, combined with improved customer satisfaction and the potential for growth, makes your garage a standout choice in the automotive competitive market.

The software is designed to significantly enhance customer retention for your garage. efficiently managing appointments, accurate billing, vehicle inspection and personalized communication contributes to overall customer satisfaction As a result, your garage becomes a preferred choice, encouraging clients to return for future services.

We understand that managing a garage involves a range of tasks, so we’ve crafted an interface that simplifies the process. Even if you’re not tech-savvy, you’ll find the software easy to grasp, allowing you to efficiently manage your garage operations and provide top-notch service to your customers without any unnecessary complications.